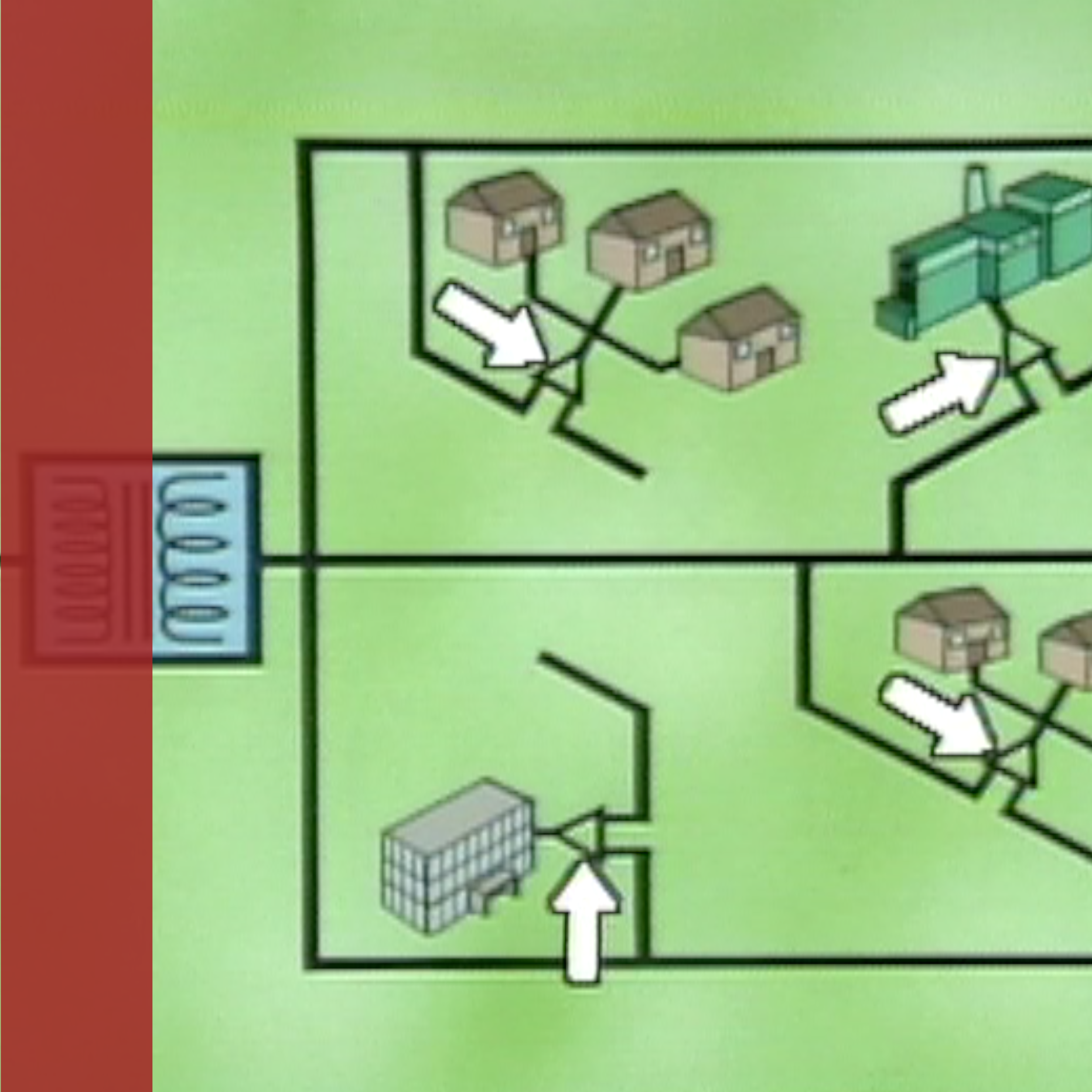

Introduction to Transmission and Distribution Systems

This course explains, in general terms, how transmission and distribution systems deliver power from a power plant to customers. The course describes the major components of a typical T&D system, how they function, and how electricity flows through these components on its journey from the power plant to customers.

Transmission

This program is designed to provide an introduction to the basic components that make up a transmission line. The program presents a basic overview of structures, conductors, and insulators commonly found on transmission lines. The program also covers the basic tasks that must be accomplished in order to build a transmission line.

Distribution

This course is designed to help personnel recognize the basic elements of a distribution system and to gain an understanding of how each element works. This course also introduces basic equipment such as transformers, capacitors, regulators, circuit breakers, and other types of protective devices.

Substations and Switchyards

This course examines the role that substations and switchyards play in a T&D system. The course provides an overview of the purposes and functions of the major equipment used in substations and switchyards. Equipment used for protection, regulation, monitoring, and communication is introduced.

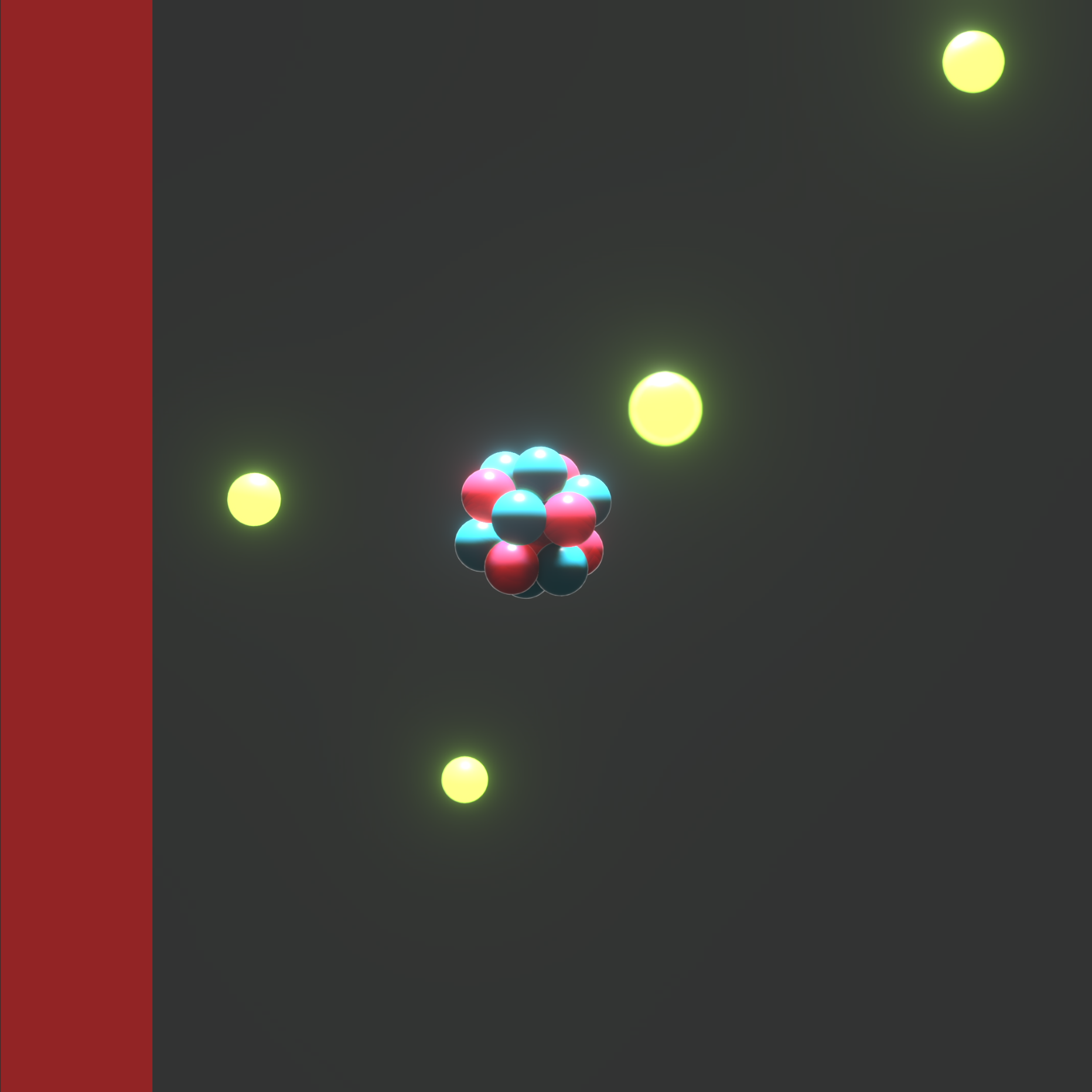

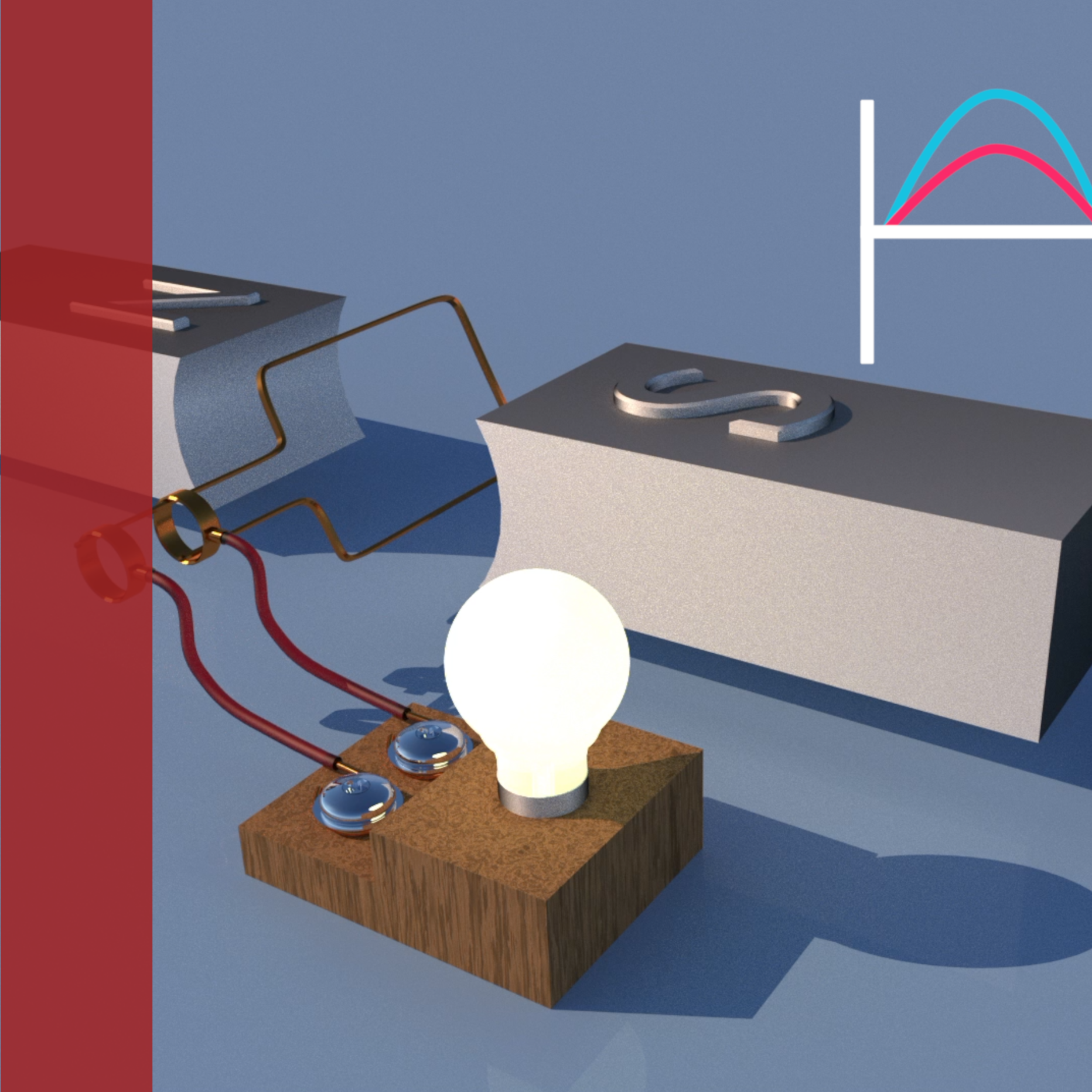

Basic Electricity Review

Modern electrical systems contain a great deal of electrical equipment that needs to be maintained and repaired. To perform electrical maintenance tasks correctly and efficiently, Lineworkers must have (1) a basic understanding of the fundamentals of electrical theory; (2) a specific knowledge of the way electrical devices operate; and (3) practical hands-on experience.

Alternating Current Fundamentals

Most of the electrical equipment used today operates on alternating current (AC). The purpose of this training unit is to review significant terms, concepts, and principles associated with alternating current.

Climbing Wooden Poles

In order to climb safely and efficiently, a lineworker needs to understand and practice climbing techniques. This program introduces methods used for climbing wooden poles with a fall restraint, as well as non-fall restraint climbing. The program demonstrates proper techniques for placing gaffes on a pole, safetying-on and off a pole, methods of adjusting a fall restraint while working on a pole, and the basic technique of maneuvering around a pole.

Safety in Transmission and Distribution Maintenance

This course is designed to familiarize trainees with the basic safe work practices and safety equipment that are used in transmission and distribution maintenance work.

Using Tools

This program describes the basic hand and power tools commonly used in distribution work. The program presents guidelines for using manual hand tools, power hand tools, and one type of powder-actuated tool. The program also covers the safety precautions that should be followed when using each type of tool.

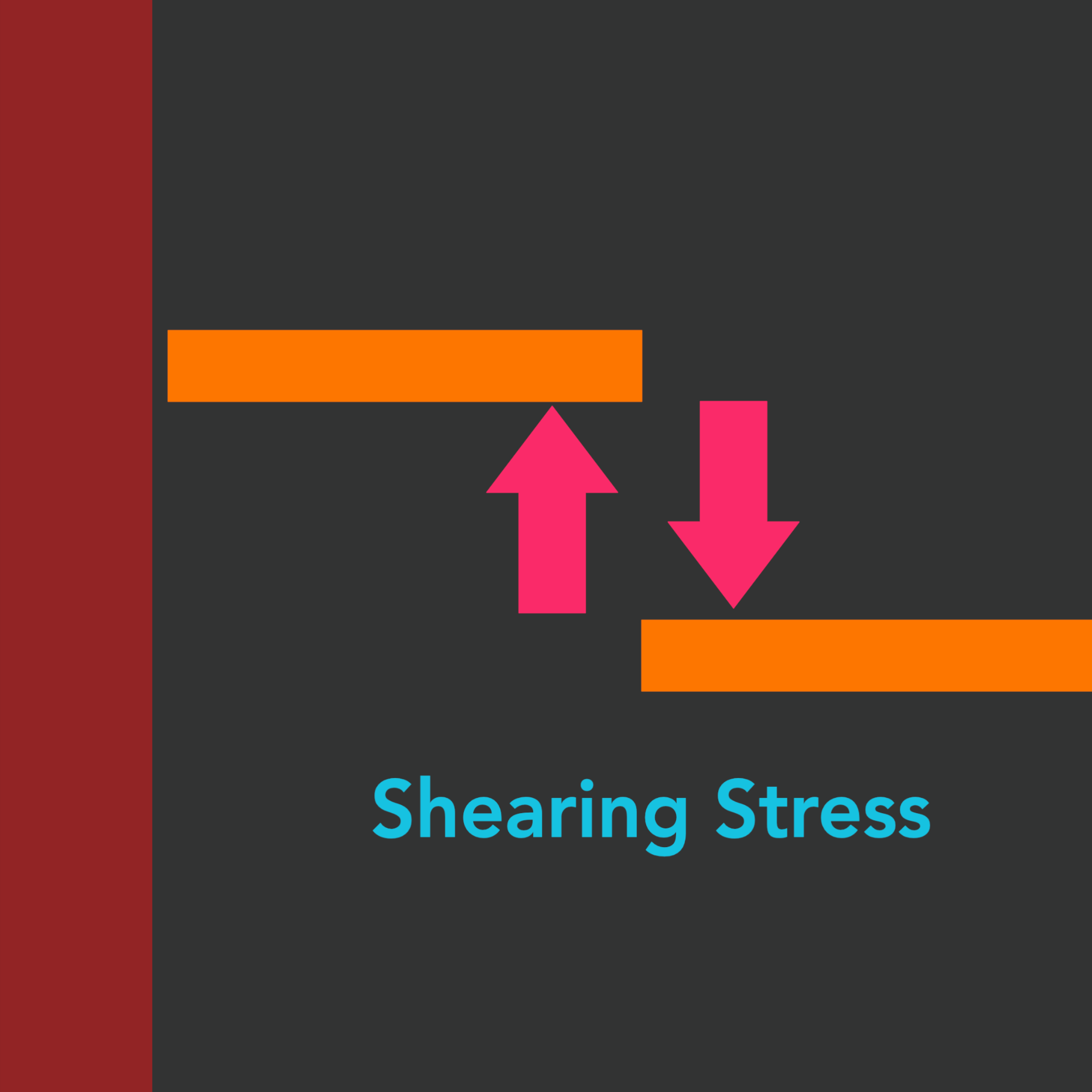

Rigging 1

Line crews are constantly required to use ropes, blocks, and other special equipment to raise and lower electrical components, tools, and equipment. In order to perform these tasks safely and efficiently, a fundamental knowledge of rigging and rigging equipment is necessary. This program concentrates on the basics of overhead rigging, including safe rigging practices, ropes, knots and knot tying, the use of handlines, and the use of blocks and tackle.

Rigging 2

Many jobs performed on transmission and distribution systems require heavy loads to be rigged so that they can be lifted, moved, and stabilized while work is being done. This course identifies basic rigging equipment and discusses guidelines for rigging a job safely. It also demonstrates rigging methods using different types of rigging equipment. The following procedures are covered: rigging to lift a transformer, changing out a crossarm, and attaching secondary lines.

Electrical Safety

This course is designed to teach trainees about electrical hazards and about the protective devices and safety practices that can help prevent injuries and equipment damage on the job. The course discusses safety hazards and protective devices. It also presents a step-by-step explanation of safety practices associated with switching, tagging, testing, and protective grounding.

Hydraulic Derricks

Many tools use hydraulic power to make a job easier. Some of the common jobs on electrical systems involve lifting or digging. This program discusses the major working parts, controls, and safe operating procedures for hydraulic derricks. The program also demonstrates how to use a digger derrick to dig a hole and install a utility pole.

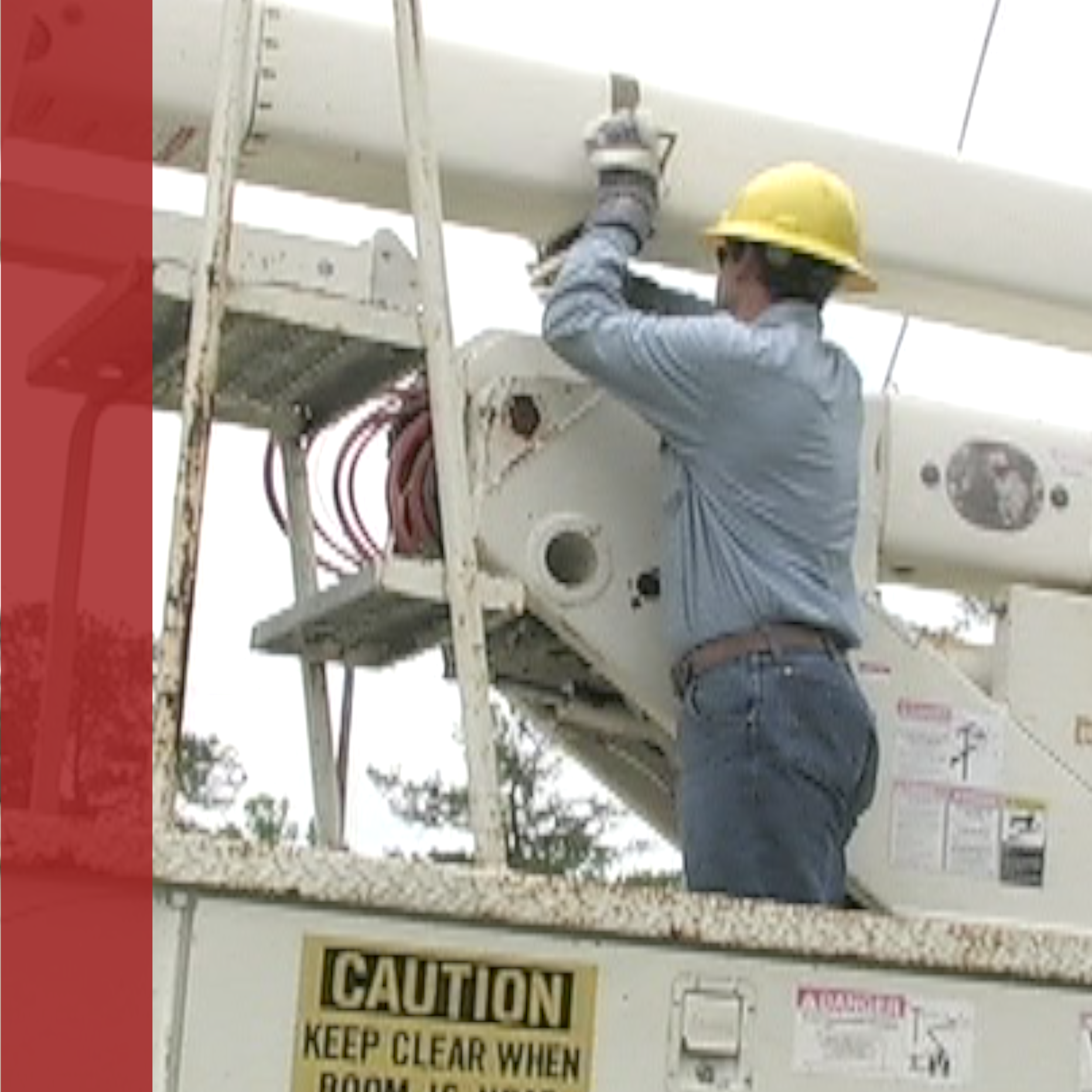

Bucket Trucks

This program addresses some of the safety guidelines that should be followed when operating a bucket truck at the job site, including a thorough pre-trip inspection. The program reviews procedures for handling traffic conditions safely and positioning bucket trucks securely on paved, unpaved, and hilly work surfaces. The program also describes safety equipment for using bucket trucks near energized lines, and guidelines for maneuvering bucket trucks around the work area. This program describes three types of outriggers used to stabilize bucket trucks. The program also demonstrates procedures for positioning and setting up a bucket truck with outriggers at a rural site, establishing a job site and setting up a bucket truck at an intersection, and maneuvering a bucket and boom around the work area.

Material Handling Bucket Trucks

Material handling bucket trucks are modified versions of the traditional bucket truck. They are designed specifically to handle moderate sized loads in addition to supporting personnel in buckets. While the two types of Bucket Trucks may look very much alike, there are important operational differences between them and operating a material handling bucket truck safely, requires knowledge of these differences and training in the skills to properly handle loads.

System Protection and Monitoring

This course discusses the principles of protection and monitoring in a transmission and distribution system. The course explains the role of protective devices, system grounds, and monitoring and control equipment. Techniques for installing or replacing ground rods, arresters, and fuse links are presented. The course also describes how monitoring and control equipment is typically used in a transmission and distribution system.

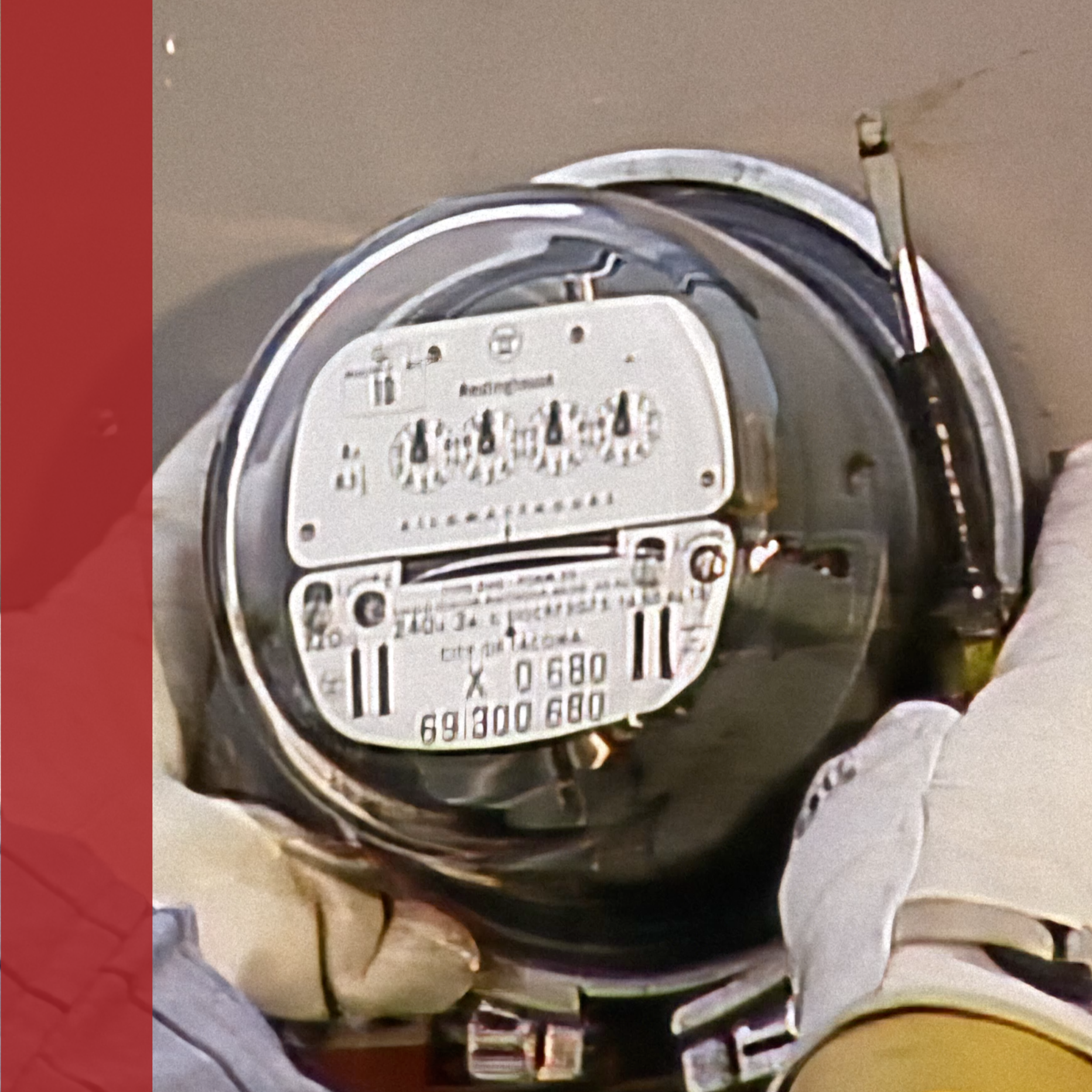

Introduction to Metering

This course is designed to present an overview of kilowatt-hour meters and meter operation. Although the program is intended to be introductory, several devices, procedures, and concepts presented assume a familiarity with basic electrical theory and distribution systems. Students without this prior training may require additional explanation or instruction.

Bucket Truck Rescue

This course demonstrates how to perform a bucket truck rescue. Trainees will see how to lower the boom in an emergency, and two ways to extract an incapacitated person from a bucket. This course also demonstrates the importance of being able to act quickly and decisively during an emergency situation.

Safety in Meter Work

This course covers the hazards and basic safety guidelines associated with meter work and emphasizes working safely near energized equipment, using caution when approaching potentially hazardous conditions, and using protective equipment properly.

Safety in Substations and Switchyards

This program focuses on the basic safety principles and practices applicable to substations and switchyard maintenance work. The program describes electrical, chemical, and personal hazards that may be encountered in substations and switchyards. General procedures for responding to imminent dangers and accidents are also presented.