Overhead Distribution Systems

This training program is designed to familiarize students with the various types of weights and tensions associated with rigging in line work. The safety factor for a job that includes rigging is also covered. The procedures and concepts presented assume a familiarity with basic electrical theory and transmission and distribution systems.

Service Installation

This course describes basic procedures for installing and connecting services. The course describes common types of service connectors, and demonstrates the basic steps involved in making a service connection. The course also demonstrates procedures for installing both overhead and underground residential services. This course describes three types of voltage tests that should be performed before making service connections. The course also describes procedures involved in installing a three-phase service and replacing a three-phase service without interrupting service to the customer. Typical safety practices and job preparations are also covered.

Pole Framing and Guying

The main function of a utility pole is to support conductors. Because conductors are heavy, they can pull on a pole with a great deal of force. The equipment on a pole that supports the conductors must be constructed to withstand this force. This course describes methods used to frame a pole, that is, how to install crossarms and other conductor supports. This course also describes methods of supporting a pole using several different types of guying techniques.

Setting and Replacing Poles

This program presents some of the equipment and methods that can be used to set utility poles. The program describes three methods for digging holes, and outlines both power-operated and manual methods for installing poles. The program also includes guidelines for installing poles in open areas and safety considerations for installing poles around obstacles and energized lines. Additionally, this course describes basic methods for removing and replacing poles.

Safety in Overhead Line Maintenance

This course examines hazards that may be present during overhead line maintenance operations. The course also introduces protective equipment designed to create a barrier between lineworkers and high voltage lines and equipment, and reviews safety practices that will help ensure a safe work environment.

Multimeter Operation

In this course trainees learn the difference between analog and digital multimeters, and how to read and use both types of multimeters. Trainees can then use their knowledge of multimeters in a variety of applications.

Tree Trimming

Trees are common throughout the service areas covered by many utilities. When trees grow into, over, or near energized equipment, they may cause interruptions in electrical service, particularly during storms or strong winds. During an emergency, a tree crew may not be available, and it may not be possible to postpone a job. Lineworkers often handle small tree trimming jobs or work as part of a crew to clear large trees from power lines. This program describes basic methods of tree trimming as well as some of the hazards associated with tree trimming work and precautions that should be taken.

Safe Bucket Truck Operation

This course covers several aspects of bucket truck safety, including how to inspect a bucket truck prior to use, how to plan a job with safety in mind, and how to avoid shock hazards associated with working on or near bucket trucks.

Working on Distribution Poles

This program reviews some of the factors involved in planning a distribution job, including safety guidelines and site-specific considerations. The program also describes some of the conductors commonly used in secondary construction. In addition, the program reviews the basic procedures for paralleling a service with and without the use of a jumper.

Distribution Line Safety

This course introduces students to the principles and techniques of single-point, or equipotential grounding. For best results, students should have a basic knowledge of electrical theory, overhead distribution systems and equipment, grounding theory, equipment, and application and common work methods and procedures used in overhead distribution line maintenance.

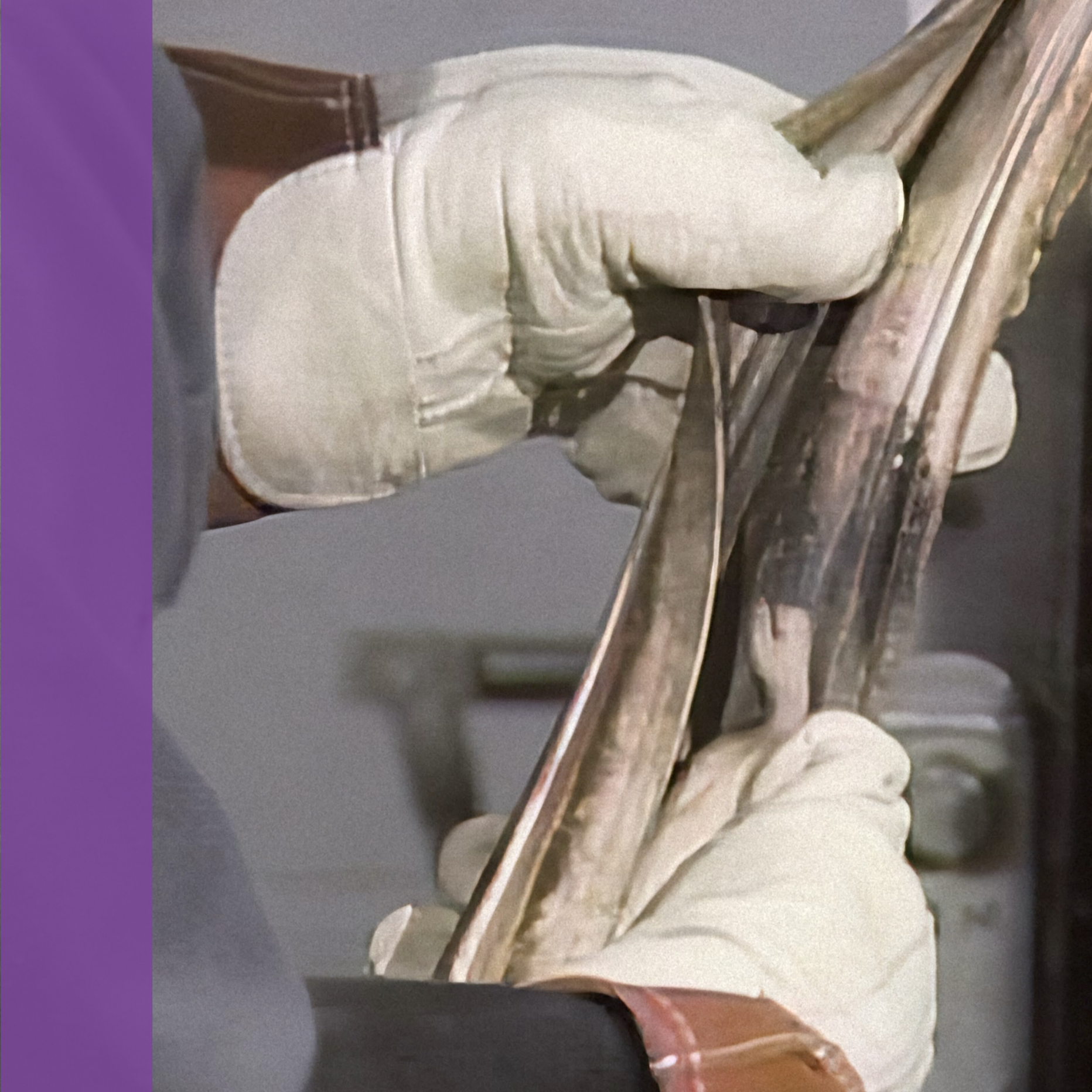

Care and Testing of Tools and Equipment

This program reviews the fundamentals of caring for, storing, and inspecting some of the tools and equipment used in transmission and distribution work. The program demonstrates how to perform visual inspections, field inspections, and dielectric tests on rubber protective gear, line hose, hoods, mechanical jumpers, and hot sticks.