Power Transformers 2

This course demonstrates how to recognize and identify specific classes of power transformers by their sealing systems and discusses how these sealing systems work.

Circuit Breakers 1

Part one of this course provides the trainee with an overview of circuit breakers and their operating principles. It also introduces the student to the fundamental concepts of arc extinguishing and circuit interruption. At the conclusion of this course, students should be able to describe the main functions of circuit breakers and identify them by their classification. In addition, they should be able to identify air-magnetic, air-blast, oil, and vacuum circuit breakers, and briefly describe how each one operates.

Circuit Breakers 2

This training program is designed to provide the student with basic information about circuit breakers that are used in substations and switchyards. The course shows how arcs are extinguished in gas-blast and gas-puffer breakers, and covers four types of breaker operating mechanisms: solenoid, motor/spring, pneumatic, and hydraulic.

Voltage Regulators 1

Utilities are required to provide power to their customers within a specific range of voltages. Voltages that are outside of that range may damage equipment or cause it to operate inefficiently. One method of maintaining voltage within a specified range is by using voltage regulators. This program discusses the operation and control of substation voltage regulators.

Voltage Regulators 2

This program describes the general procedures for performing voltage regulator field inspections and control checks. The program also describes how to remove a voltage regulator from service and how to put a new or replacement regulator into service.

Capacitors and Reactors

Conditions exist in any transmission and distribution system that result in power losses in the systems and equipment that deliver power and in the systems and equipment that use power. In order to compensate for these power losses, utilities often use devices such as capacitor banks and shunt reactors.

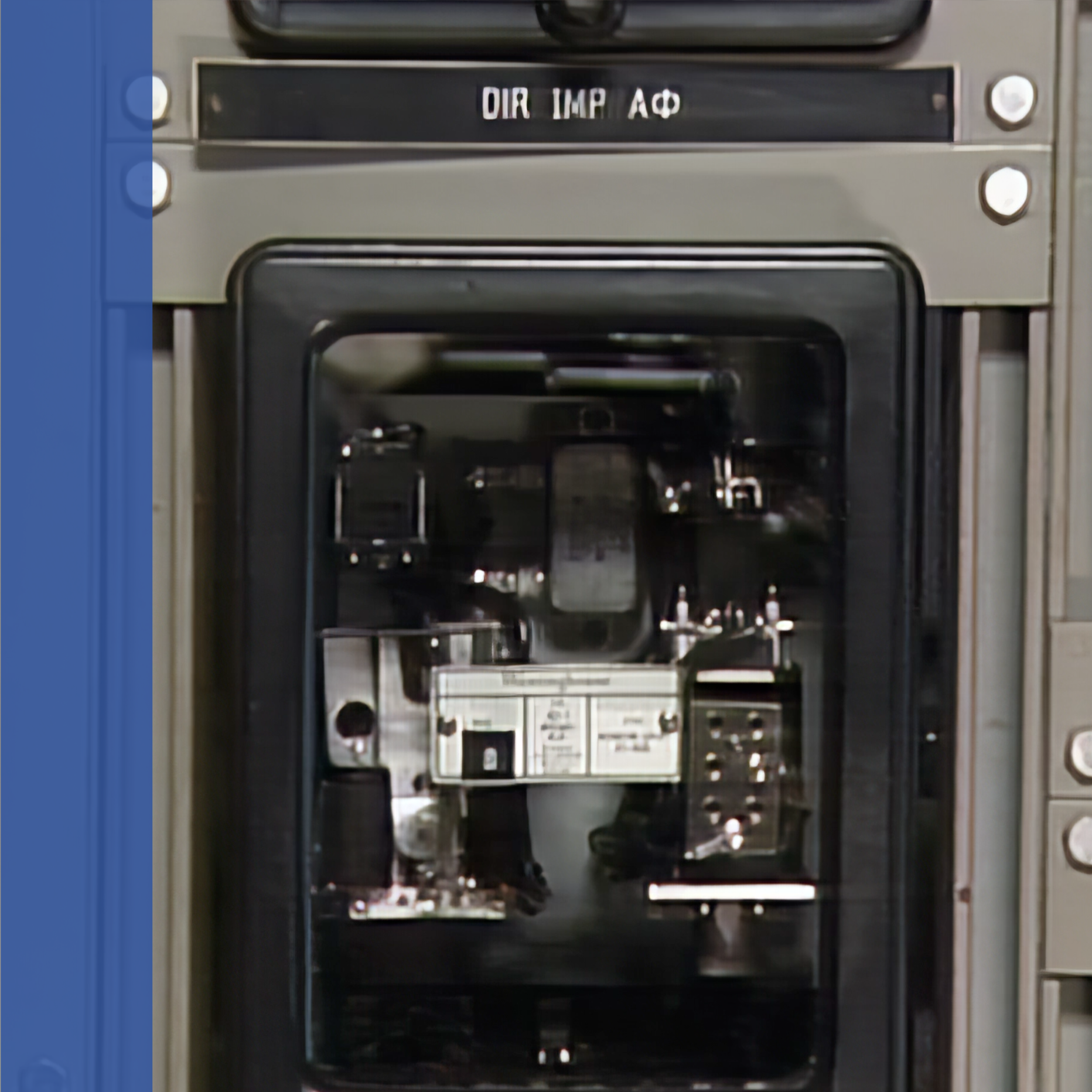

Relays 1

When a fault occurs in a transmission and distribution (T&D) system, current increases and voltage decreases. The increased current causes excessive heating, which, depending on where the fault occurs, can result in a fire or an explosion. If the fault is not quickly isolated, it can damage that may result in loss of service.

T&D systems use various types of control systems to detect and isolate faults with minimum disturbance. A key component of all of these control systems is the protective relay.

Relays 2

An electric power system includes generators, power transformers, transmission lines, switchgear, distribution circuits, and residential and business customer equipment. At any time, severe weather, accidents, or other factors may cause part of the system to fail. If the system is not properly protected, a failure can result in personal injuries and extensive equipment damage. One of the keys to protecting equipment and personnel from failures is the use protective relays.

Control Equipment

Disturbances and failures in a transmission and distribution (T&D) system can interrupt customer service and damage system equipment. Control equipment is the general name given to devices designed to minimize the effects of disturbances and failures. Control equipment helps to limit the number of customers affected by a given disturbance, as well as limit damage to the T&D system.

High Voltage Terminations

High-voltage cables are manufactured to exact specifications so that they can withstand a variety of mechanical and electrical stresses. When a high-voltage cable is terminated for a connection to a circuit or equipment in a substation or switchyard, the termination must also be made to exact specifications. If this is not done, the termination could become a weak point in the circuit.

Transmission Structures

Transmission lines and the structures that support them are key components to any transmission and distribution system. There are many different kinds of transmission structures, and each is designed to meet various power delivery needs and geographic considerations. Assembling and erecting a transmission structure requires planning, teamwork, and careful attention to detail.

Transmission Line Safety

The most important concern in transmission line work is accomplishing each job safely. Safety on the job requires making the effort necessary to control working conditions, work practices, and human actions. Personal injuries and equipment damage are minimized when safe work practices are followed and when the hazards associated with transmission line work are minimized or eliminated.

Climbing Steel Poles and Towers

Steel poles and towers used for transmission lines come in a variety of shapes, sized, and designs. Experience and practice are necessary in order to climb these structures safely and efficiently. This training unit presents a basic overview of the tools and equipment, planning, and techniques necessary for climbing steel poles and towers.

Transmission Line Installation

Transmission line installation is a complex job that requires extensive planning, careful coordination or manpower and equipment, and a thorough mastery of construction procedures and techniques. This training program focuses on the part of that job involved with installing conductors on a structure.

Rigging for High Voltage Line Work

Maintenance work on transmission lines is frequently done while the lines remain energized. Working on energized lines saves money and allows for uninterrupted customer service. Live-line work is possible, in part, because of special rigging tools and equipment that have developed to allow lineworkers to do the work safely and efficiently.

Working on Deenergized Transmission Lines

Transmission lines have characteristics that make them different from distribution lines. Because of the high voltages associated with transmission lines and the increasing use of multiple transmission lines on a given right-of-way, or even on individual structures, lineworkers who work on de-energized transmission lines need to be aware of some special considerations.

Transmission Line Repair - Hot Sticks

Taking transmission lines out of service for repairs or maintenance can be difficult and costly. For this reason, transmission lines are often worked on while they are energized. The two basic methods of working on energized lines are the bare hand method and the hot stick method. With the bare hand method, special tools and equipment allow direct contact with an energized conductor. With the hot stick method, insulated poles and other equipment are used to protect lineworkers from energized conductors.

Transmission Line Repair - Bare Hand Method

The increased demand for electricity in recent years has made it necessary for power companies to build more transmission lines and more extra high voltage (EHV) transmission lines. Taking these lines out of service for repairs or maintenance can be costly and difficult. As a result, lines are often worked on while they are energized. The two basic methods of working on energized lines are the hot stick method and the bare hand method. With the hot stick method, insulated poles are used to protect the lineworkers from energized conductors. With the bare hand method, special tools and equipment allow direct contact with an energized conductor.